Risk assessment

Analysis and risk assessment of hazardous production facilities (HPF)

On the oil and gas production facilities, due to the high aggressiveness of the extracted product, the analysis and risk assessment are even more relevant.

An important aspect of safety in the construction and operation of oil and gas production facilities is the accounting and processing of all possible risks and their consequences in the framework of the project. These works aim for identification, analysis and control the risks of large-scale accidents.

GOST R ISO 17776-2012 (Oil and gas industry. Offshore mining installations. Methods and techniques for hazard identification and risk assessment. The main provisions present some definitions:

- Risk is a combination of the possibility or probability of an event and the occurrence of the consequences of the risk;

- Risk analysis is a systematic process of information processing for hazard identification and risk assessment;

- Risk assessment is a process of risk analysis and measurement.

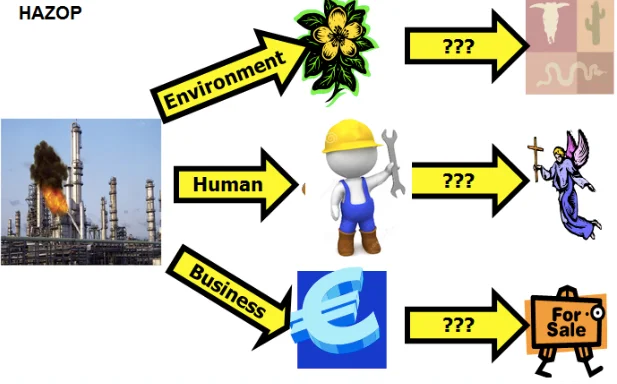

Risks lead to such consequences as:

- Multiple victims or deaths,

- Significant financial losses,

- Environmental disasters or other negative social and cultural effects,

- Adversely affects to the company reputation at the international and national levels.

The main objective of risk identification and assessment is to use risk as a basis for prioritizing and managing the inspection program, where the equipment to be inspected is evaluated according to the degree of risk. In almost every situation, once a risk has been identified, there are alternatives to mitigate it. On the other hand, almost all major business losses are the results of failure to understand or manage risk.

The main types of work on risk assessment and solutions for HSE (Health, Safety and Environment):

- The procedure of risk identification and assessment (HAZID, HAZOP).

- Impact analysis and impact modelling.

- Calculation and modeling of hydrodynamic processes (CFD).

- Hazard analysis of toxic gases, including hydrogen sulfide.

- Risk analysis of low-temperature processes.

- Qualitative and quantitative risk assessment (HRA).

- Researches of availability, reliability and maintainability of the equipment.

- Based on the principle of reasonable sufficiency (ALARP).

- Development and application of work standards.

- Evaluation of the Safety Integrity Level (SIL) and Layers of Protection Analysis (LOPA).

- Risk assessment for the facility construction.

- Emergency exit, evacuation and rescue analysis (EERA).

- Preliminary planning of emergency response plans.

- Emergency System Survivability Analysis (ESSA).

- Studies of falling objects.

- Studies of flare emissions.

- Noise analysis.

- Analysis by the method of butterfly diagram.

- Investigation of incidents.

- Development and implementation of a complete HSE-Case (Health, Safety and Environment).

- Development of HSE management systems.

- Environmental management.

- Design and operation of enterprises taking into account the human factor and engineering psychology.

- Cultural and behavioural improvements.

- Business risk assessment.

- Project risk management.

- Knowledge management in the enterprise.

- Security management.

- Overall support to HSE: policy, planning, procedures, systems safety, audits and accident investigation.

Risk assessment as part of the implementation of various processes

Risk assessment as part of the implementation of various processes, such as the transport on offshore fields, makes sense to develop a comprehensive safety assessment for individual operating structures. The methodology for this analysis is identical to the development and implementation of full HSE-Case in the enterprise.

covering the following key steps:

- Identification of potential hazards and consequences;

- Assessment of potential impacts/outcomes and the likelihood of their occurrence;

- Identification of controls available to prevent or minimize the likelihood of hazards and consequences;

- Definition of recovering measures to mitigate impacts;

- Search for further possible risk mitigation measures.

In its simplest form, this process involves:

- Hazard identification (HAZID);

- Hazard-related risk assessment using a risk matrix by comparing it with acceptable risk criteria; Identification of control methods (barriers) available to prevent the occurrence of risks or to minimize their consequences; Further analysis and assessment of risks at a level proportional to the risk;

- Identification and analysis of possible additional risk mitigation measures.

The major risks are those associated with major accidents, which can lead to:

- Several deaths;

- Significant loss of assets;

- Massive environmental or socio-cultural effects;

- International negative impact on the company reputation.

The major risks require careful risk analysis by the method of butterfly diagrams (Bowties) to identify barriers, controls and recovery measures. Additionally, the quantitative risk assessment is also carried out. For example, for an offshore platform, the scope of work can include the following activities:

- Assessment of Maritime operations.

- Evaluation of ground logistics processes – transportation of materials and personnel.

- Evaluation of ground-based warehouse operations.

- Assessment of port operations.

- Evaluation of helicopter operations.

- Evaluation of operations related to the delivery of goods by aircraft.

- Evaluation of waste generation operations.

The result of work is the conclusion that in order to ensure the safe operation of the facility there is a sufficient number of methods of control of the HSE (Health, Safety and Environment) and, therefore, the hazardous production facility meets the requirements that are necessary for the continuation of its safe operation.